Our Services

Okinox is also providing Installation, Validation & Commissioning services to valued clients in India and abroad.

Installation

Commissioning

Validation

Providing Mechanical Utilities

Pure Steam

Cooling Water

Raw Water

Soft Water

Chilled Water

Vacuum

ETP Piping

Compressed Air

Steam (IBR/Non IBR)

LPG, Nitrogen & Hydrogen

Condensate Recovery

Mechanical Installation

Orbital Welding

Boroscopy

Passivation

Electropolishing

Sterilization & Sanitization

Product Categories

High Purity Water Generation System

Okinox is providing US Pharmacopoeia as well as a WHO-approved pharmaceutical water generation system for customers’ high-quality needs.

- Pre-Treatment

- Pure Steam Generator

- RO-EDI System

- WFI Generation Plant

- Multi Column Distillation Plant

- DM Plant

- CIP/SIP System

- Ultra-Filtration Membranes

High Purity Water Storage & Distribution System

Okinox High Purity Water Storage and Distribution System are generally used for storage of PW and WFI in pharmaceutical plants.

- SS Tanks & Filter Housing

- Electro-polished Tubes & Fittings

- Sanitary Pumps, Zero Dead-Leg Valves & Instruments

- SS Utility Pendants

- Sanitary Heat Exchangers

- Ozonisation System

Our Products

Pre-Treatment

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant. Providing a reliable, high-quality supply of treated water is critical to many processes.

However, selecting the right Pre-Treatment technologies is very essential in the field of water treatment. It requires a comprehensive evaluation of the raw water quality and process requirements, the system design, operating conditions, and economics. We Okinox have the experience and expertise to specify the right pre-treatment system for standard applications and custom design systems to meet specialized needs.

RO-EDI System

RODI takes the RO/DI approach a step further with modern technology. Membrane filtration technologies (including ceramic membranes) allow our systems to treat feed waters that are typically considered unsuitable as a source of high purity water. This is especially important in more remote parts of the world. We use continuous electro deionization (EDI) as the ion exchange process in our systems.

Unlike conventional ion exchange, EDI uses electricity to continuously regenerate the ion exchange resin and eliminates the use of hazardous acid and caustic necessary for regenerating conventional ion exchange systems. Any of our HPW or UPW systems can be equipped with remote monitoring capabilities that allow us to monitor the performance of the entire system, provide guidance on operation, and predict upcoming maintenance issues.

DM Plant

DM Plant is the process of removing mineral salts from water by using the ion exchange process. The DM plants are loaded with highly efficient CATION and ANION exchangers and are also loaded with a degasification system to remove every trace of minerals from the system.

WFI Generation Plant

Okinox has been the leading supplier of plants producing water for injection, which meets international standards, including USP, IP, BP and JP. The plants are manufactured as per FDA’s current Good Manufacturing Practices (cGMP) and ASME requirements and follows the basic principle of Distillation by Thin Film Evaporation. This process involves shell and tube heat exchangers (columns) where heat transfer is done by falling film evaporation. Very high temperatures are reached for every drop of water produced, thus ensuring sterility levels demanded WFI. Separation of the Pyrogenic load is achieved through centrifugal forces generated during the upward movement of the steam.

Pure Steam Generator

The Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. The benefit of the Use Okinox CIP System is that the cleaning is faster, less labour- intensive and more repeatable, and poses less chemical exposure risk to people.

The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports. This may be done to reduce the bio-burden on the system or to kill harmful materials at the end of a batch. Okinox SIP system will ensure that all areas being steamed have been exposed to live steam for an adequate time to ensure the desired “kill” effect.

SS Tanks & Housing

With enriched market experience we have been able to offer a wide spectrum of SS Filter Housings. We are one of the most trusted names of the market known for offering an excellent range of Stainless-Steel Filter Housings to the valued clients. These housings are manufactured using standard quality of stainless steel procured from some of the trusted sources of the industry. Okinox Stainless Steel Vent Filter housings are used for various pharmaceutical manufacturing machineries like high purity water storage tank, WFI water storage tank, Sugar syrup tanks as well as other product contact vessels for pharmaceutical industries.

CIP/SIP System

The Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. The benefit of the Use Okinox CIP System is that the cleaning is faster, less labour- intensive and more repeatable, and poses less chemical exposure risk to people.

The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports. This may be done to reduce the bio-burden on the system or to kill harmful materials at the end of a batch. Okinox SIP system will ensure that all areas being steamed have been exposed to live steam for an adequate time to ensure the desired “kill” effect.

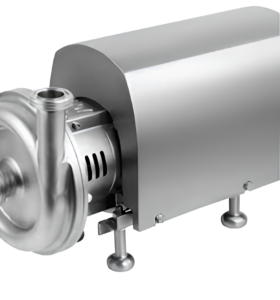

Sanitary Pumps, Zero Dead-Leg Valves & Instruments

SS 304/ SS 316 MOC Sanitary Design. These components are popularly used in Pharmaceutical industries for quick and accurate

control/change/divert as per the flow in a pipeline. the diaphragm can be available with different MOC like TEFLON/EPDM/SILICON/VITON. End connection can be Tri clover ends/ weld neck or SMS unions.

Electro-Polished Tubes & Fittings

We have emerged as the foremost Importer- Exporter, manufacturer, and Supplier of Stainless- Steel Tubes, Fittings and Valves. Clients can avail these products from us in various specifications according to their needs.

SS Utility Pendants

SS Utility Pendants finds application in pharmaceutical industries and is available in different options. We are offering this pendant at a suitable price. These pendants are made as per customer requirements for connecting utilities like purified water, water for injection, chilled water, hot water, compressed air in pharmaceutical industries and are made up of Stainless-Steel Grade 304. Our organization is widely reputed in offering Stainless Steel Utility Pendants to our clients. Okinox is a manufacturer and service provider for various engineering utilities like orbital welding service, process piping service, boiler piping service, compressed air piping services for pharmaceutical, healthcare, food-beverages, chemical, textile, oil, and various industries.

Sanitary Heat Exchangers

Okinox sanitary shell & tube heat exchangers are designed to meet the high-quality requirements and hygienic standards of the pharmaceutical industry. All product contact surfaces have a maximum surface finish of 20pin (0.5μm) Ra, and can be improved to 15pin (0.38μm) Ra or better with optional electropolishing. Available with a single tubesheet or double tubesheet to eliminate the risk of cross-contamination between the product and working fluids.

Ozonisation System

Ozonation (also referred to as ozonisation) is a chemical water treatment technique based on the infusion of ozone into water. Ozone is a gas composed of three oxygen atoms (03), which is one of the most powerful oxidants. Ozonation is a type of advanced oxidation process, involving the production of very reactive oxygen species able to attack a wide range of organic compounds and all microorganisms.

The treatment of water with ozone has a wide range of applications, as it is efficient for disinfection as well as for the degradation of organic and inorganic pollutants. Ozone is produced with the use of energy by subjecting oxygen (02) to high electric voltage or to UV radiation. The required amounts of ozone can be produced at the point of use but the production requires a lot of energy.

What we do?

Okinox is also providing installation, Validation &commissioning services to valued clients in India and abroad.

Installation

Commissioning

Validation

Providing Mechanical Utilities

Steam

(IBR/ Non-IBR)

Condensate Recovery

Pure Steam

Soft Water

Chilled Water

Cooling Water

Raw Water

Compressed Air

Vacuum

LPG, Nitrogen & Hydrogen

ETP Piping

Mechanical Installation

Orbital Welding

Boroscopy

Passivation

Electropolishing

Sterilization & Sanitization

High Purity Water Generation System

Okinox Understand How Important It Is to Obtain A Choice Of Water Qualities. Okinox High Purity Water Generation System Are Designed and Developed for Treating Water Of Different Sources and Quality. In pharmaceuticals, Healthcare, Biotech, Food & Beverages, Water is most commonly used in Liquid foam, not only as a Process Use but also as a cleaning agent.

Okinox is providing US Pharmacopoeia as well as a WHO-approved pharmaceutical water generation system for customers high-quality needs.

Pre-Treatment

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant. Providing a reliable, high-quality supply of treated water is critical to many processes.

However, selecting the right Pre-Treatment technologies is very essential in the field of water treatment. It requires a comprehensive evaluation of the raw water quality and process requirements, the system design, operating conditions, and economics. We Okinox have the experience and expertise to specify the right pre-treatment system for standard applications and custom design systems to meet specialized needs.

RO-EDI System

RODI takes the RO/DI approach a step further with modern technology. Membrane filtration technologies (including ceramic membranes) allow our systems to treat feed waters that are typically considered unsuitable as a source of high purity water. This is especially important in more remote parts of the world. We use continuous electro deionization (EDI) as the ion exchange process in our systems.

Unlike conventional ion exchange, EDI uses electricity to continuously regenerate the ion exchange resin and eliminates the use of hazardous acid and caustic necessary for regenerating conventional ion exchange systems. Any of our HPW or UPW systems can be equipped with remote monitoring capabilities that allow us to monitor the performance of the entire system, provide guidance on operation, and predict upcoming maintenance issues.

DM Plant

DM Plant is the process of removing mineral salts from water by using the ion exchange process. The DM plants are loaded with highly efficient CATION and ANION exchangers and are also loaded with a degasification system to remove every trace of minerals from the system.

WFI Generation Plant

Okinox has been the leading supplier of plants producing water for injection, which meets international standards, including USP, IP, BP and JP. The plants are manufactured as per FDA’s current Good Manufacturing Practices (cGMP) and ASME requirements and follows the basic principle of Distillation by Thin Film Evaporation. This process involves shell and tube heat exchangers (columns) where heat transfer is done by falling film evaporation. Very high temperatures are reached for every drop of water produced, thus ensuring sterility levels demanded WFI. Separation of the Pyrogenic load is achieved through centrifugal forces generated during the upward movement of the steam.

Pure Steam Generator

The Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. The benefit of the Use Okinox CIP System is that the cleaning is faster, less labour-intensive and more repeatable, and poses less chemical exposure risk to people.

The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports. This may be done to reduce the bio-burden on the system or to kill harmful materials at the end of a batch. Okinox SIP system will ensure that all areas being steamed have been exposed to live steam for an adequate time to ensure the desired “kill” effect.

CIP/SIP System

The Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. The benefit of the Use Okinox CIP System is that the cleaning is faster, less labour-intensive and more repeatable, and poses less chemical exposure risk to people.

The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports. This may be done to reduce the bio-burden on the system or to kill harmful materials at the end of a batch. Okinox SIP system will ensure that all areas being steamed have been exposed to live steam for an adequate time to ensure the desired “kill” effect.

High Purity Water Storage & Distribution System

Okinox High Purity Water Storage and Distribution System are generally used for storage of PW and WFI in pharmaceutical plants. Provided System is Fully Automated and Integrated with Programmable Logic Control to Achieve Complete System as per CGMP (Current Good Manufacturing Practice), WHO as well as USP & as per Our Clients Requirements. Application areas of the high purity water system is pharmaceutical industries, healthcare industries, food and beverages, Milk processing industries as well as textile industries.

SS Tanks & Housing

With enriched market experience we have been able to offer a wide spectrum of SS Filter Housings. We are one of the most trusted names of the market known for offering an excellent range of Stainless-Steel Filter Housings to the valued clients. These housings are manufactured using standard quality of stainless steel procured from some of the trusted sources of the industry. Okinox Stainless Steel Vent Filter housings are used for various pharmaceutical manufacturing machineries like high purity water storage tank, WFI water storage tank, Sugar syrup tanks as well as other product contact vessels for pharmaceutical industries.

Sanitary Pumps, Zero Dead-Leg Valves & Instruments

SS 304/ SS 316 MOC Sanitary Design. These components are popularly used in Pharmaceutical industries for quick and accurate control/change/divert as per the flow in a pipeline. the diaphragm can be available with different MOC like TEFLON/EPDM/SILICON/VITON. End connection can be Tri clover ends/ weld neck or SMS unions.

Electro-Polished Tubes & Fittings

We have emerged as the foremost Importer-Exporter, manufacturer, and Supplier of Stainless-Steel Tubes, Fittings and Valves. Clients can avail these products from us in various specifications according to their needs.

SS Utility Pendants

SS Utility Pendants finds application in pharmaceutical industries and is available in different options. We are offering this pendant at a suitable price. These pendants are made as per customer requirements for connecting utilities like purified water, water for injection, chilled water, hot water, compressed air in pharmaceutical industries and are made up of Stainless-Steel Grade 304. Our organization is widely reputed in offering Stainless Steel Utility Pendants to our clients. Okinox is a manufacturer and service provider for various engineering utilities like orbital welding service, process piping service, boiler piping service, compressed air piping services for pharmaceutical, healthcare, food-beverages, chemical, textile, oil, and various industries.

Sanitary Heat Exchangers

Okinox sanitary shell & tube heat exchangers are designed to meet the high-quality requirements and hygienic standards of the pharmaceutical industry. All product contact surfaces have a maximum surface finish of 20µin (0.5µm) Ra, and can be improved to 15µin (0.38µm) Ra or better with optional electropolishing. Available with a single tubesheet or double tubesheet to eliminate the risk of cross-contamination between the product and working fluids.

Ozonisation System

Ozonation (also referred to as ozonisation) is a chemical water treatment technique based on the infusion of ozone into water. Ozone is a gas composed of three oxygen atoms (O3), which is one of the most powerful oxidants. Ozonation is a type of advanced oxidation process, involving the production of very reactive oxygen species able to attack a wide range of organic compounds and all microorganisms.

The treatment of water with ozone has a wide range of applications, as it is efficient for disinfection as well as for the degradation of organic and inorganic pollutants. Ozone is produced with the use of energy by subjecting oxygen (O2) to high electric voltage or to UV radiation. The required amounts of ozone can be produced at the point of use but the production requires a lot of energy.